Today, we will discuss high-purity sulfur.

Sulfur is a common element with diverse applications. It is found in gunpowder (one of the “Four Great Inventions”), used in traditional Chinese medicine for its antimicrobial properties, and employed in rubber vulcanization to enhance material performance. High-purity sulfur, however, has even broader applications:

Key Applications of High-Purity Sulfur

1. Electronics Industry

o Semiconductor Materials: Used to prepare sulfide semiconductors (e.g., cadmium sulfide, zinc sulfide) or as a dopant to improve material properties.

o Lithium Batteries: High-purity sulfur is a critical component of lithium-sulfur battery cathodes; its purity directly impacts energy density and cycle life.

2. Chemical Synthesis

o Production of high-purity sulfuric acid, sulfur dioxide, and other chemicals, or as a sulfur source in organic synthesis (e.g., pharmaceutical intermediates).

3. Optical Materials

o Fabrication of infrared lenses and window materials (e.g., chalcogenide glasses) due to high transmittance in specific wavelength ranges.

4. Pharmaceuticals

o Raw material for drugs (e.g., sulfur ointments) or carriers for radioisotope labeling.

5. Scientific Research

o Synthesis of superconducting materials, quantum dots, or nano-sulfur particles, requiring ultra-high purity.

________________________________________

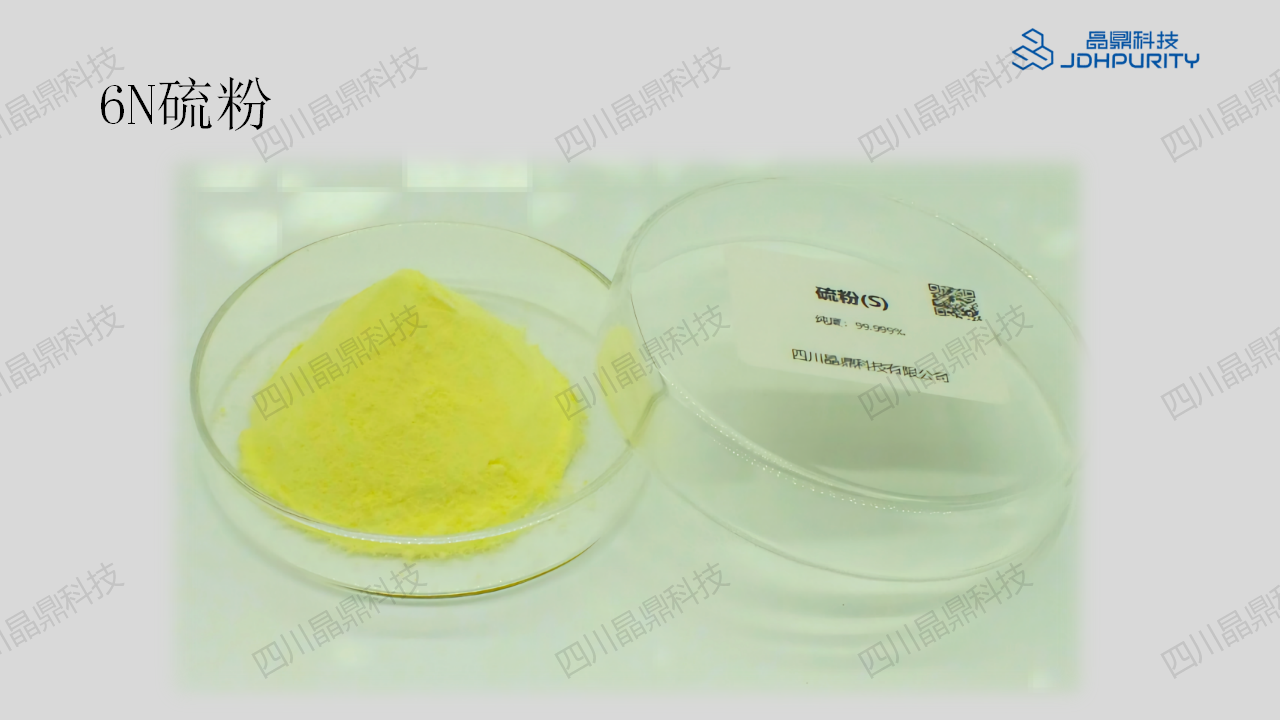

High-Purity Sulfur Purification Methods by Sichuan Jingding Technology

The company produces 6N (99.9999%) electronic-grade high-purity sulfur using the following techniques:

1. Distillation

o Principle: Separates sulfur (boiling point: 444.6°C) from impurities via vacuum or atmospheric distillation.

o Pros: Industrial-scale production.

o Cons: May retain impurities with similar boiling points.

2. Zone Refining

o Principle: Moves a molten zone to exploit impurity segregation between solid and liquid phases.

o Pros: Achieves ultra-high purity (>99.999%).

o Cons: Low efficiency, high cost; suitable for lab or small-scale production.

3. Chemical Vapor Deposition (CVD)

o Principle: Decomposes gaseous sulfides (e.g., H₂S) to deposit high-purity sulfur on substrates.

o Pros: Ideal for thin-film materials with extreme purity.

o Cons: Complex equipment.

4. Solvent Crystallization

o Principle: Recrystallizes sulfur using solvents (e.g., CS₂, toluene) to remove impurities.

o Pros: Effective for organic impurities.

o Cons: Requires handling toxic solvents.

________________________________________

Process Optimization for Electronic/Optical Grade (99.9999%+)

Combinations such as zone refining + CVD or CVD + solvent crystallization are employed. The purification strategy is tailored to impurity types and purity requirements, ensuring efficiency and precision.

approach exemplifies how hybrid methods enable flexible, high-performance purification for cutting-edge applications in electronics, energy storage, and advanced materials.

Post time: Mar-24-2025